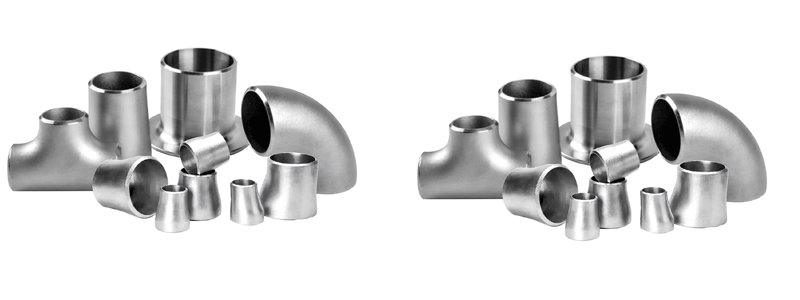

The SS 316 pipe fittings are known to be of high resistance to corrosion, tensile strength as well as for the industrial environment which is very demanding. SS 316 fittings are manufactured in molybdenum-added stainless steel which provides a better level of resistance against corrosion caused by chlorides, thus makes them ideal in marine, chemical and pharmaceutical use. These fittings guarantee leak-free, secure performance in vital piping systems which deal with corrosive fluids, high pressure as well as variable temperature.

As industries move toward safer and more reliable piping solutions, the demand for SS 316 pipe fittings continues to rise. Whether used in food processing, petrochemical plants, or offshore environments, SS 316 fittings ensure durability, hygiene, and operational efficiency. Their ability to withstand harsh conditions makes them one of the most preferred stainless steel grades across the globe.

Steelage Alloys is one of the leading manufacturers, suppliers, and exporters of SS 316 pipe fittings in India, recognized for delivering high-quality stainless steel products that meet international standards. With modern manufacturing facilities, advanced CNC machinery, and a skilled engineering team, Steelage Alloys has built a strong reputation as a trusted brand in the stainless steel industry.

The company specialises in the manufacture of accurate, reliable and durable SS 316 pipe fittings of various industries. With the usual fittings to the tailor-made designs, Steelage Alloys guarantees perfection at all phases of manufacturing. The company has been able to serve its clients throughout India by keeping quality control, delivery on time, and customer-focused policies.

Stainless Steel 316 (also known as Marine Grade Stainless Steel) is an austenitic alloy containing 16% chromium, 10% nickel, and 2–3% molybdenum. The addition of molybdenum significantly enhances its corrosion resistance compared to SS 304, especially in chloride-rich and acidic environments.

These exceptional properties make SS 304 pipe fittings ideal for industrial piping systems, plumbing applications, and structural processes.

| Fitting Type | Subtypes / Varieties | Function / Application |

|---|---|---|

| SS 316 Elbows | 45° Elbow, 90° Elbow, Long Radius, Short Radius | Used to change the direction of flow smoothly |

| SS 316 Tees | Equal Tee, Reducing Tee | Used for branching the pipeline |

| SS 316 Reducers | Concentric Reducer, Eccentric Reducer | Ideal for connecting different pipe sizes |

| SS 316 Couplings | Full Coupling, Half Coupling | Used for reliable connections between pipes |

| SS 316 Caps & End Caps | Pipe Cap, End Cap | Used to close pipe ends securely and prevent leakage |

| SS 316 Stub Ends | Long Stub End, Short Stub End | Used with lap joint flanges for easy assembly/maintenance |

| SS 316 Unions | Union | Allow easy dismantling of sections during maintenance |

| SS 316 Cross Fittings | Cross | Used in four-way pipelines to distribute fluid flow |

| SS 316 Nipples | Threaded Nipple, Welded Nipple | Used for pipe extensions—available in threaded/welded forms |

| Customized SS 316 Fittings | As per client drawing/spec | Designed to meet specific industrial/engineering needs |

Steelage Alloys is recognized as one of the most trusted and reliable manufacturers, suppliers, and exporters of SS 316 pipe fittings in India due to its strong focus on quality, precision, and customer satisfaction. The company adheres to strict international standards such as ASTM, ASME, and DIN, ensuring every SS 316 fitting delivers superior corrosion resistance, strength, and durability even in the most demanding industrial environments. With advanced manufacturing facilities, skilled technicians, and state-of-the-art CNC machinery, Steelage Alloys consistently delivers dimensionally accurate and high-performance SS 316 fittings suitable for chemical, marine, pharmaceutical, and petrochemical applications.

Formula: m = (OD - THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926...

Plastic Bag

Wooden case

By Sea

By Air