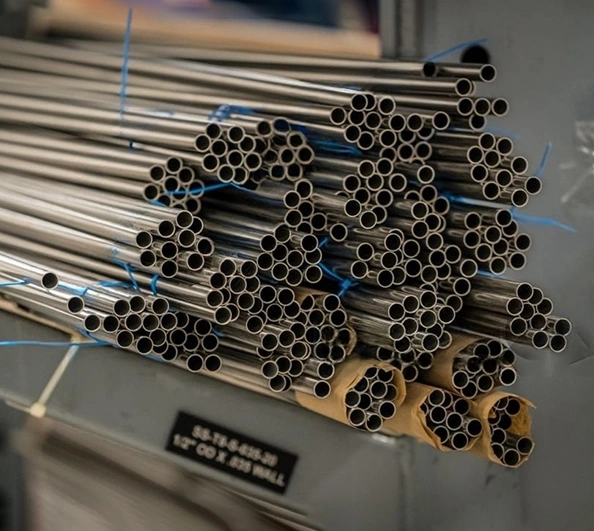

Steelage Alloys offers precision-manufactured Stainless Steel Capillary Tubes, known for their ultra-fine dimensions, corrosion resistance, and consistent performance in critical applications. These tubes are designed for precise fluid and gas flow, making them ideal for industries such as medical instrumentation, chromatography, thermocouples, hydraulics, and chemical processing.

Crafted from high-grade stainless steel (typically SS 304, 304L, 316, 316L), our capillary tubes are available in various diameters and wall thicknesses to suit highly specific application needs. Each tube is produced under strict quality control to ensure a smooth internal surface, accurate dimensions, and exceptional purity, ensuring reliable performance even in high-pressure or high-temperature environments.

Corrosion Resistant

Trusted Supplier

Bulk Orders

Formula: m = (OD - THK) × THK (mm) × L (m) × 0.02491

* For 316, 316L, 310S, 309S, etc., ratio=0.02507

OD = Outer diameter, THK = Wall Thickness, L = Length

Plastic Bag

Wooden case

By Sea

By Air