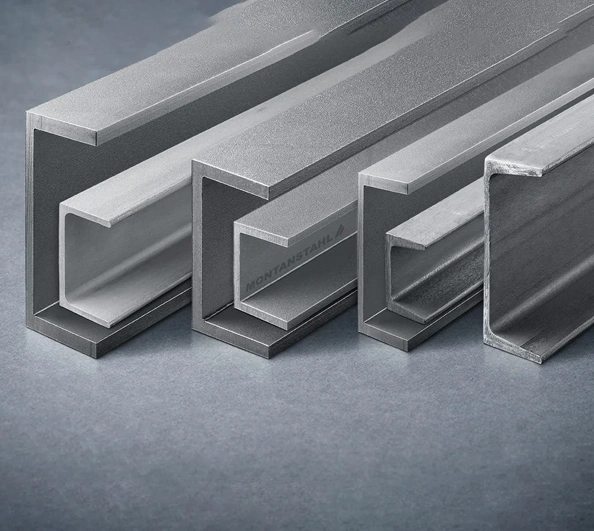

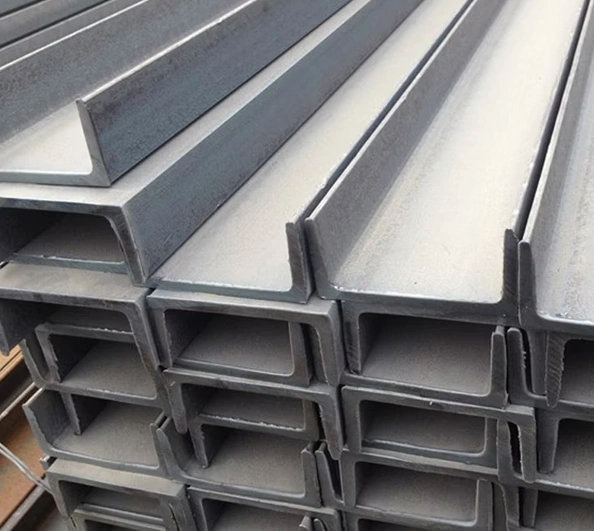

As an experienced SS 316 c channel manufacturer in India, we at SteelAge Alloys provide well-attested and highly-produced stainless steel channel bars, which are used to provide strength, support, and durability with a broad array of structural and architectural materials. A U-shaped profile on these bars lends them a good load-supporting ability, which is why the bars are used in construction flats, in machinery as support, and in industrial floors. Our channel bars work under heavy- industrial pressure while they contribute to the modern design aboard their clean lines and corrosion-resistant finish on the interior and exterior.

Corrosion Resistant

Trusted Supplier

Bulk Orders

As one of the biggest 304 channel suppliers in India, we supply to diverse industries that include infrastructure, fabrication, transportation, and marine. They can be fabricated, welded, and installed on a simple basis without any complications also versatile for both light-duty purposes and heavy-duty purposes. We strive for overall quality of product, delivering on time and full customer satisfaction, which ensures that our channel bars are of high standards both in the nation and globally.

Formula : m = [D × TW + 2 × TF × (B - TW) + 0.349 × (R1 × R1 - R2 × R2)] × L (m) × 0.0.00793 * For 316, 316L, 310S, 309S, etc., ratio=0.00798. For 400 series stainless steel, ratio=0.00775 D = Flange Depth, B = Flange Width, TW = Web Thickness, TF = Flange Thickness, R1 = Radius R1, R2 = Radius R2

Formula :m = [D × TW + 2 × TF × (B - TW) + 0.615 × (R1 × R1 - R2 × R2)] × L (m) × 0.0.00793 * For 316, 316L, 310S, 309S, etc., ratio=0.00798. For 400 series stainless steel, ratio=0.00775 D = Flange Depth, B = Flange Width, TW = Web Thickness, TF = Flange Thickness, R1 = Radius R1, R2 = Radius R2

Plastic Bag

Wooden case

By Sea

By Air