The selection of the appropriate Stainless Steel Hex Bar Manufacturer in India is a major choice to the industries that need high dimensional precision, toughness, and corrosiveness. The stainless steel hex bars are commonly applicable in precision machining and fabrication processes where dependability and consistency are the most important considerations.

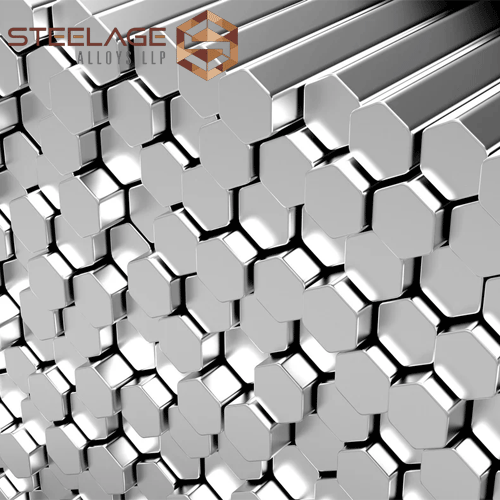

When it comes to stainless steel hex bars, superior raw material quality, precise shape, and uniform surface finish are essential. This is where we stand apart as a trusted stainless steel hex bar manufacturer in India. Our hex bars are produced using premium-grade stainless steel and advanced manufacturing processes to ensure excellent machinability and long-term performance.

Advanced Manufacturing Technology

Our stainless steel hex bars are manufactured through the current production methods and the high quality raw materials. Exact rolling, precise sizing and regulated heat treatment provide excellent mechanical qualities and uniform quality. We are a long time manufacturer of stainless steel hex bars, so our products are of high standards according to international standards and are reliable and strong.

As a reliable business partner we assure you our product quality defines best in world. We are giving our extensive expertise knowledge in stainless steel industry. We are offer our product as most competitive price in market. Delivering superior quality of stainless steel which meets the rigorous demands of modern industries. On these pipes we are applying several quality tests. Our SS 316 Pipes are made up of the best quality raw material to prevent rust. Our Pipes have a long service life, and less maintenance is required. 316 having prominent quality because of molybdenum which provide grade 316 with better overall corrosion resistant properties. It’s mainly helps to offer higher resistance to pitting corrosion in any environment.

| Specification Item | Details |

|---|---|

| Product Name | Stainless Steel Hex Bar |

| Shape | Hexagonal |

| Material Grade | SS 304 / SS 316 / SS 310 / SS 321 / Duplex / Super Duplex |

| Standard Compliance | ASTM A276, ASTM A479, EN 10088, IS 6603 |

| Manufacturing Process | Hot Rolled / Cold Drawn |

| Size Range (AF) | 8 mm to 80 mm |

| Length | 3 m, 6 m, or as per customer requirement |

| Surface Finish | Black, Bright, Polished, Turned |

| Tolerance | H8 / H9 or as per standard |

| Density | 7.9 – 8.0 g/cm³ |

| Tensile Strength | ≥ 515 MPa (SS 316) |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 35% |

| Hardness | Max 217 HB |

Formula: m = (OD - THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926...

Plastic Bag

Wooden case

By Sea

By Air