Engineered for Maximum Corrosion Resistance: Our SS 316 Seamless Pipes & Tubes

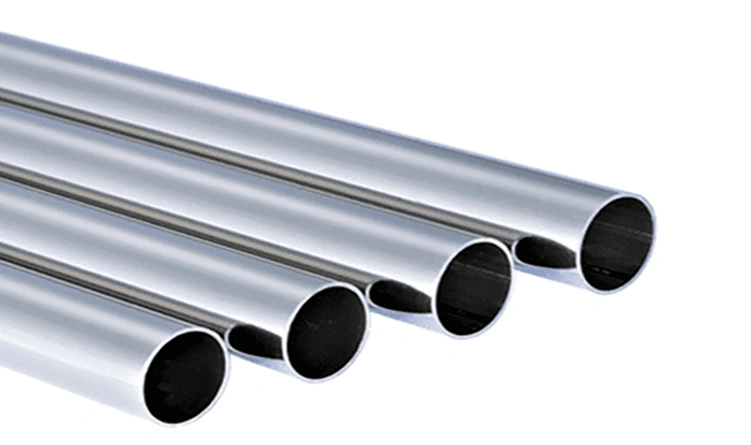

Our SS316 seamless pipes and tubes are made of high-quality austenitic stainless steel of 16 18 percent chromium, 10 14 percent nickel, and 2 3 percent molybdenum. It is a composition that provides our pipes with high corrosion resistance, high durability, and high temperature strength. The 316 grade, according to the AISI/ASTM standards, is our effort to offer the strongest stainless steel to be used in chemical, marine, and industrial applications where reliability and lifespan are paramount. Recognized as a reputed SS 316 seamless pipe manufacturer and SS 316 seamless tube suppliers in India, we deliver services that maximize efficiency and performance.

SteelAge Alloys LLP manufactures its SS 316 seamless tubes in a seamless process. To manufacture solid billets with uniform wall thickness, leak-proof construction, and high-pressure tolerance, we heat, pierce, and stretch solid billets over mandrels. By so doing, we can provide pipes that resist extreme industrial environments, work effectively in pipelines, heat exchangers, and building structures, and require few repairs over decades.

Our SS 316 pipes and tubes are used in critical applications where corrosion resistance, ductility, and weldability are required. We provide piping systems to chemical processing facilities, marine systems and offshore systems, pharmaceutical and food processing systems, oil and gas pipelines, and heat exchangers. The molybdenum content of the alloy makes it highly resistant to chlorides and acids, resulting in us being able to offer products that last longer and perform better when subjected to tough environments.

Formula: m = (OD - THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926...

Plastic Bag

Wooden case

By Sea

By Air