The question of which SS 316 Flat Bar exporter to choose is not one that should be decided in haste.

When it comes to SS 316 Flat Bars, quality, corrosion resistance, strength, and reliability are essential. At Steelage Alloys, we stand out as a trusted SS 316 Flat Bar exporter, delivering premium-grade stainless steel products that meet international standards. You can place your complete trust in Steelage Alloys for high-performance SS 316 flat bars suitable for demanding industrial applications.

Understanding Your Requirements

It is important to understand what SS 316 Flat Bars are and why choosing the right exporter matters. SS 316 is an austenitic stainless steel alloy enriched with molybdenum, which significantly enhances its resistance to corrosion, especially in chloride-rich and marine environments.

SS 316 flat bars are widely used in industries where strength, durability, and resistance to harsh chemicals are critical. Applications include chemical processing, marine engineering, pharmaceuticals, food processing, oil & gas, and power generation. In such sectors, material purity and dimensional accuracy play a vital role, making the choice of exporter crucial.

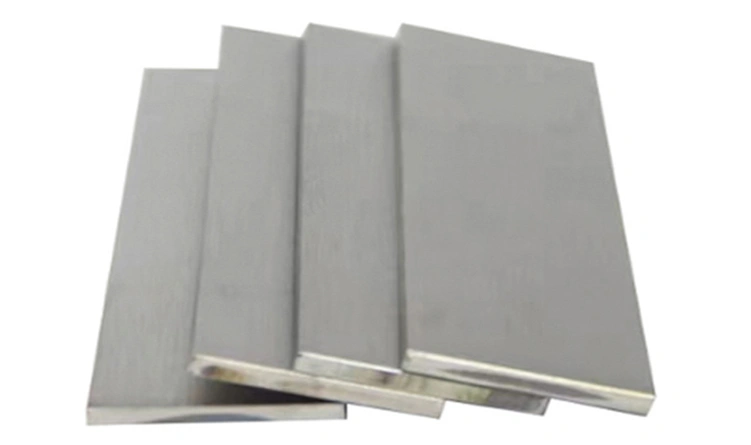

At Steelage Alloys, we manufacture and export SS 316 flat bars using high-quality raw materials and advanced production techniques. Our flat bars offer excellent mechanical properties, superior surface finish, and long service life even under extreme operating conditions.

We ensure strict quality control at every stage of production, from raw material selection to final inspection. Our SS 316 flat bars are available in various sizes, thicknesses, and custom specifications to meet diverse client requirements across global markets.

| Property | SS 316 Flat Bar Specifications |

|---|---|

| Material Grade | Stainless Steel 316 (UNS S31600) |

| Standards | ASTM A276 / ASTM A240 / ASME SA276 |

| Width Range | 12 mm to 200 mm (custom sizes available) |

| Thickness Range | 3 mm to 50 mm |

| Length | 3 meters, 6 meters, or cut-to-length as required |

| Surface Finish | Hot Rolled (HR), Cold Drawn (CD), Pickled, Polished |

| Form | Flat Bar |

| Manufacturing Process | Hot Rolled / Cold Drawn |

| Tolerance | As per ASTM standards or customer specification |

| Condition | Annealed / Solution Treated |

Formula : m = A (mm) × THK (mm) × L (m) × 0.00793 * For 316, 316L, 310S, 309S, etc., ratio=0.00798. For 400 series stainless steel, ratio=0.00775 A = Side width, THK = Thickness, L = Length

Plastic Bag

Wooden case

By Sea

By Air