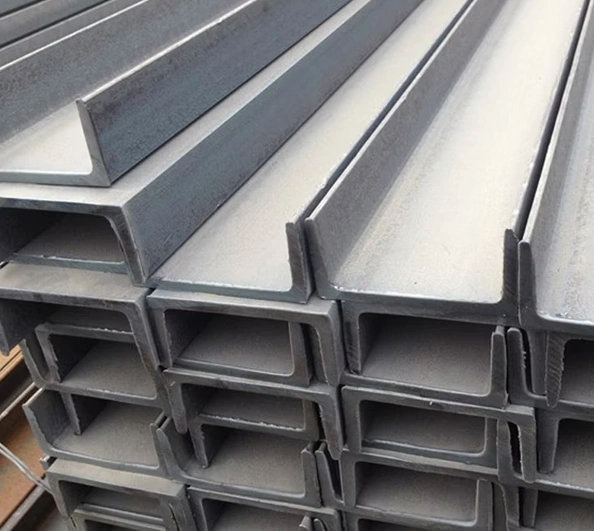

Steelage Alloys is a reputable SS 316 C Channel Manufacturer in India, which produces high-quality stainless steel structural channel with an aim of satisfying the stringent needs of the modern industries. Our SS 316 C Channels are produced with the best grade of austenitic stainless steel, which is augmented with molybdenum to be more resistant to corrosion particularly in high chloride and hostile conditions.

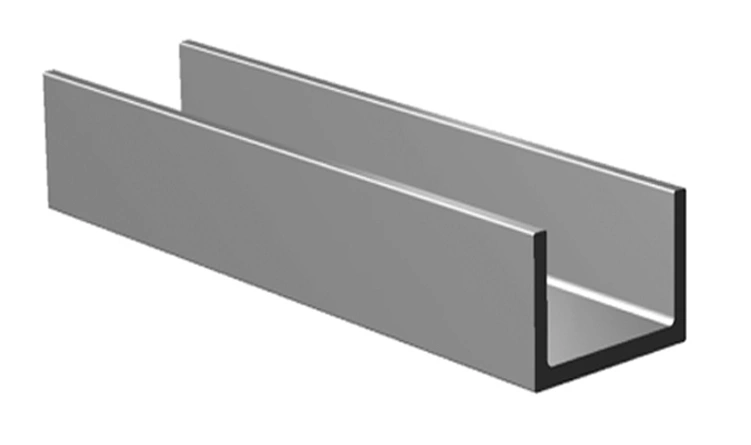

An SS 316 C Channel is a structural stainless steel section manufactured in a “C” or channel-shaped profile using SS 316 grade stainless steel. It is widely used in construction, fabrication, and industrial frameworks where high strength and excellent corrosion resistance are required.

SS 316 is an austenitic stainless steel alloy that contains chromium, nickel, and molybdenum. The addition of molybdenum gives SS 316 C Channels superior resistance to pitting, crevice corrosion, and chemical attack, especially in chloride-rich, marine, and chemical environments. This makes them more corrosion-resistant than SS 304 channels.

Before choosing the material, it is important to know what SS 316 C Channels offer and why the right grade makes a difference. SS 316 is an austenitic stainless steel containing molybdenum, which enhances resistance to pitting, crevice corrosion, and chemical attack—particularly in marine and high-chloride environments.

These channels are extensively used in chemical industries, offshore and marine structures, oil and gas plants, pharmaceutical manufacturing, food processing units, and heavy engineering projects. In such critical applications, material quality, mechanical strength, and precise dimensions play a vital role in ensuring safety, durability, and reliable long-term performance.

| Property | SS 316 C Channel Value |

|---|---|

| Density | 8.0 g/cm³ |

| Melting Point | 1400°C |

| Tensile Strength | 515 MPa / 75,000 psi |

| Yield Strength | 205 MPa / 30,000 psi |

| Elongation | 35% |

| Composition | Cr 16-18%, Ni 11-14%, Mo 2-3% |

| Thickness | 3.0mm – 120mm |

| Length | 3MTR–6MTR (customizable) |

| Size (mm) | Weight (kg/m) |

|---|---|

| 40×20 | 1.78–2.30 |

| 50×25 | 3.86 |

| 100×50 | 10.60 |

| 200×75 | 25.30 |

| 400×110 | 71.80 |

Formula : m = [D × TW + 2 × TF × (B - TW) + 0.349 × (R1 × R1 - R2 × R2)] × L (m) × 0.0.00793 * For 316, 316L, 310S, 309S, etc., ratio=0.00798. For 400 series stainless steel, ratio=0.00775 D = Flange Depth, B = Flange Width, TW = Web Thickness, TF = Flange Thickness, R1 = Radius R1, R2 = Radius R2

Formula :m = [D × TW + 2 × TF × (B - TW) + 0.615 × (R1 × R1 - R2 × R2)] × L (m) × 0.0.00793 * For 316, 316L, 310S, 309S, etc., ratio=0.00798. For 400 series stainless steel, ratio=0.00775 D = Flange Depth, B = Flange Width, TW = Web Thickness, TF = Flange Thickness, R1 = Radius R1, R2 = Radius R2

Plastic Bag

Wooden case

By Sea

By Air