Engineered for Corrosion Resistance: Understanding SS 304 Composition

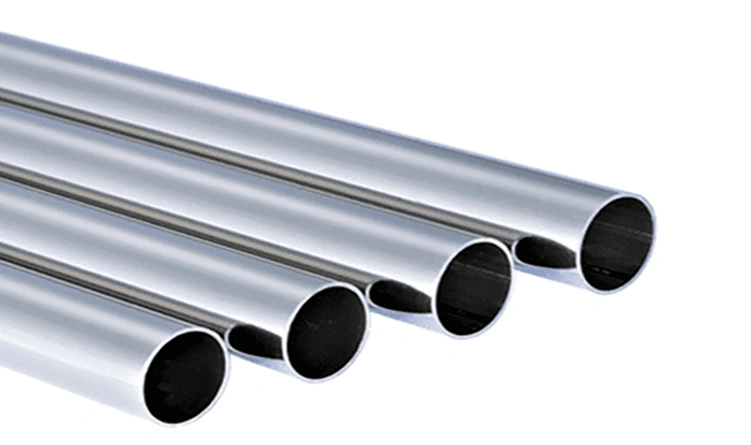

SS 304 stainless steel is a chromium-nickel alloy, consisting of some 18 percent chromium and 8 percent nickel. It is the final balance that provides it with an outstanding resistance to corrosion, huge strength in high temperatures, and resistance to extreme conditions. The AISI/ASTM designation of the 304 grade renders it the most all-around austenitic stainless steel grade. Pipes fabricated out of SS 304 are seamless and gain this structure, providing homogeneous strength and a high level of resistance to oxidation and chemical attack. Being a renowned SS 304 seamless tube suppliers and SS 304 ERW pipe manufacturer in India, we focus on creating high-impact solutions for every client.

The SS 304 seamless pipes and tubes are manufactured through high-accuracy manufacturing that eradicates welding seams. This smooth process guarantees smooth performance in terms of wall thickness, leak-proof, and high-pressure tolerance. This is produced by heating a solid stainless steel billet, stretching it over a mandrel to create the pipe. The outcome is a product that can withstand extreme mechanical loads and higher temperatures without deforming or failing.

The chromium-nickel alloy that is probably unique to SS 304 would make it suitable for food processing, chemical plants, oil and gas pipelines, and buildings. Its anti-corrosion quality enables application in wet or acidic conditions, whereas the seamless design can be used in transferring fluids safely and at high pressure. Also, the ductility and the ability to be welded enable SS 304 to be used in custom fabrications, structural frames, and in heat exchangers that will offer the benefit of reliability in the long run with minimum maintenance. We stand as your ideal SS 304 seamless pipe manufacturers in India, delivering superior and professional solutions.

Formula: m = (OD - THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926...

Plastic Bag

Wooden case

By Sea

By Air