SS 304 pipe fittings have become very popular in a variety of industries with their high resistance of corrosion, good resistance and versatile nature. Such fittings are necessary to piping systems dealing with liquids, gases, chemicals and high pressure uses. SS 304 pipe fittings will provide leak-proof, safe and efficient fluid transfer in refineries and other food processing plants.

Steelage Alloys is a reputable brand in stainless steel business in India and their business is to produce and distribute high quality SS 304 pipe fittings with a long lifespan.

Steelage Alloys is one of India’s most reputable manufacturers and suppliers of stainless steel pipe fittings, offering unmatched product quality, technical expertise, and customer support. With years of industry experience, the company delivers SS 304 pipe fittings that meet global standards such as ASTM, ASME, ISO, and DIN.

Equipped with advanced manufacturing facilities, CNC machines, and skilled engineers, Steelage Alloys produces precision components for demanding industries. The company serves clients across India and exports to several countries, making it a preferred choice for bulk and customized orders.

The best grade of stainless steel that is mostly used is Stainless Steel 304 (SS 304). It is a part of the austenitic family and it is composed of 18 percent chromium and 8 percent nickel which offers excellent corrosion resistance and mechanical strength.

These exceptional properties make SS 304 pipe fittings ideal for industrial piping systems, plumbing applications, and structural processes.

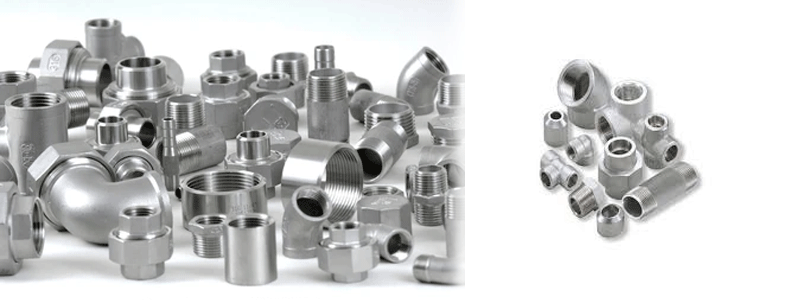

Steelage Alloys manufactures a complete range of SS 304 pipe fittings to meet diverse industrial requirements. Each product is engineered with precision and undergoes strict quality checks to ensure reliability.

| Fitting Type | Subtypes / Varieties | Function / Usage |

|---|---|---|

| Elbows | 45° Elbow, 90° Elbow, Long Radius, Short Radius | Used to change the direction of flow |

| Tees | Equal Tee, Reducing / Unequal Tee | Used for branching the pipe system |

| Reducers | Concentric Reducer, Eccentric Reducer | Used to connect pipes of different diameters |

| Couplings | Full Coupling, Half Coupling | For secure connections between pipes |

| Caps & Plugs | Pipe Cap, Plug | Used to close the end of pipelines |

| Stub Ends | Long Stub End, Short Stub End | Used with lap joint flanges |

| Unions | Standard Union | For quick dismantling and maintenance |

| Cross Fittings | 4-Way Cross | Used to divide or combine fluid flow |

Steelage Alloys has earned a strong reputation as one of the most trusted manufacturers, suppliers, and exporters of SS 304 pipe fittings in India due to its unwavering commitment to quality, precision, and customer satisfaction.What sets Steelage Alloys apart is its ability to deliver both standard and customized SS 304 fittings based on specific client requirements. With an expert engineering team, robust infrastructure, and a large production capacity, the company handles bulk orders with ease while maintaining competitive pricing.Transparent dealings, technical expertise, reliable customer support, and consistent product quality make Steelage Alloys the go-to partner for industries seeking high-performance SS 304 pipe fittings.

Formula: m = (OD - THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926...

Plastic Bag

Wooden case

By Sea

By Air