The question of which SS 304 Coil Supplier in India is the best is not something to decide in haste. Stainless steel coils are widely used in industries where strength, hygiene, and corrosion resistance are extremely important.

In SS 304 Coils, quality, reliability, and long-term performance are essential. Here’s why we are unique among SS 304 coil suppliers in India. You can place your trust in us for your industrial-grade stainless steel coil requirements.

Understanding Your Needs

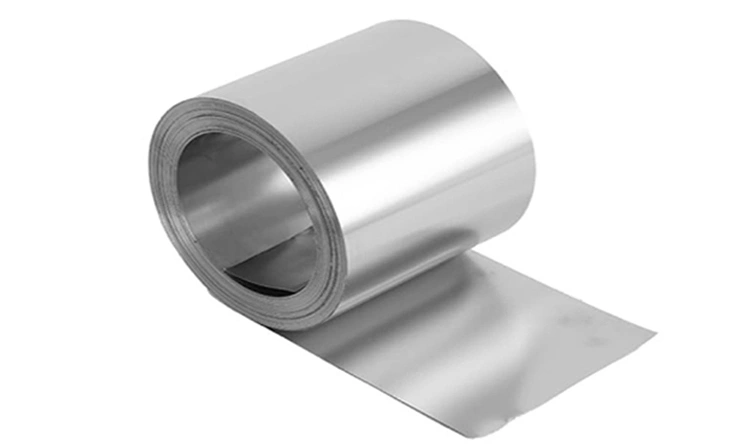

It is important to understand what an SS 304 stainless steel coil is and why it is widely preferred. SS 304 is one of the most versatile and commonly used stainless steel grades due to its excellent corrosion resistance, durability, and formability.

These coils are used for fabrication, food processing equipment, chemical machinery, heat exchangers, kitchen products, and various industrial applications. Here, the quality of stainless steel plays a significant role because the performance and lifespan of the final product depend heavily on the purity and strength of the material.

| Specification Item | Details |

|---|---|

| Material Grade | Stainless Steel 304 (UNS S30400 / 1.4301) |

| Standards | ASTM A240 / ASME SA240 |

| Manufacturing Process | Hot Rolled (HR) / Cold Rolled (CR) |

| Thickness Range | 0.3 mm to 10 mm |

| Width | Up to 2000 mm (custom sizes available) |

| Length | Coil form (custom lengths available upon request) |

| Finish Types | 2B, BA, No.4, Mirror, and custom finishes |

| Surface | Smooth, bright, polished, or matte |

| Edge | Mill Edge / Slit Edge |

| Hardness | Soft, Semi-Hard, Hard |

| Packaging | Standard export seaworthy packaging (with edge protection) |

| Testing & Certification | EN 10204 3.1 / 3.2, PMI, Mechanical & Chemical testing |

| Applications | Industrial fabrication, food-grade equipment, tanks, etc. |

Formula : m = A (m) × THK (mm) × L (m) × 7.93 * For 316, 316L, 310S, 309S, etc., ratio=7.98. For 400 series stainless steel, ratio=7.75 A = Width, THK = Thickness, L = Length

Plastic Bag

Wooden case

By Sea

By Air