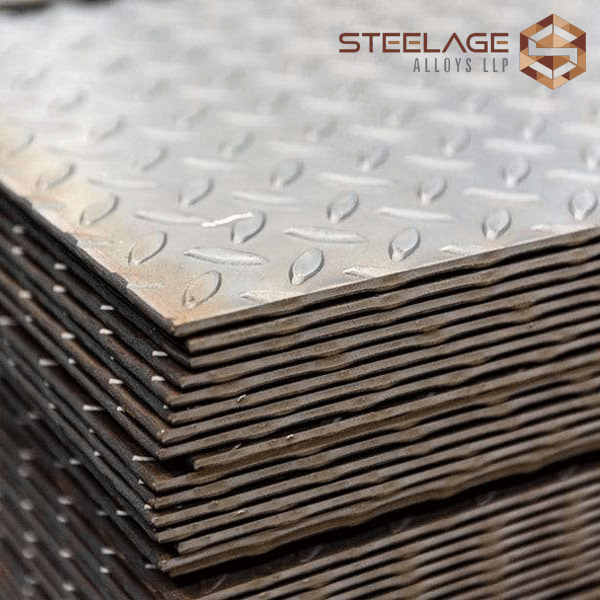

The issue of which SS 304 Chequered Plate Manufacturer in India is the best is not an issue that can be hurriedly determined. Chequered plates made of stainless steel are used where the slip resistance, durability and anti-corrosiveness are of utmost importance.

In the case of SS 304 Chequered Plates, quality, precision production and long-term performance are necessary. That is the reason why we are unique compared with SS 304 chequed plate manufacturers in India. You may well trust us with your industrial quality chequered plate stainless steel needs.

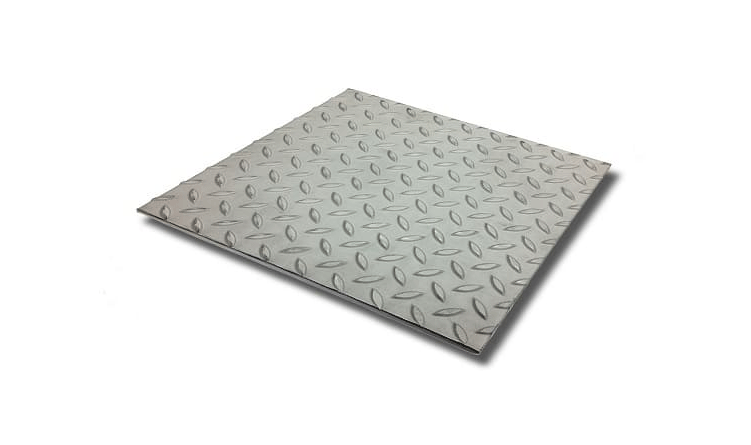

One should know what an SS 304 chequered plate is and the reason why it is mostly desirable. One of the most basic and useful grades of stainless steel used in building design and construction is SS 304 which has excellent corrosion resistance, strength and fabricability.

The SS 304 chequered plates are also broadly utilized in flooring, stair treads, ramps, walkways, platforms, walkways, transportation and industrial plants, cold storages and in places that demand anti-slip performances. These plate patterns are raised that increases grip, and therefore are suitable in the safety and heavy duty requirements.

In this case, the quality of stainless steel has significant factors as the performance and load-bearing capacity of the plate as well as their lives is determined by the purity of the material, its thickness and manufacturing uniformity.

SS 304 chequered plates are of high quality, which also guarantees high slip resistance, resistance against corrosion, and structural stability, hence the preference in various industries.

| Property | Details (SS 304 Chequered Plate) |

|---|---|

| Grade | Stainless Steel 304 (AISI 304 / UNS S30400) |

| Standards | ASTM A240 / ASME SA240 |

| Thickness Range | 3 mm to 12 mm (custom thickness available) |

| Width | 1000 mm, 1250 mm, 1500 mm (custom widths available) |

| Length | 2000 mm, 2500 mm, 3000 mm or custom cut-to-size |

| Pattern Type | Chequered / Diamond / Embossed Design |

| Finish | Hot Rolled (HR) / No. 1 Finish |

| Hardness | 150 – 200 HB (approx.) |

| Density | 8.0 g/cm³ |

| Tensile Strength | 515 MPa (minimum) |

| Yield Strength | 205 MPa (minimum) |

| Elongation | 40% (minimum) |

| Corrosion Resistance | Excellent general corrosion resistance |

| Temperature Resistance | Suitable for high-temperature applications |

Formula : m = A (m) × THK (mm) × L (m) × 7.93 * For 316, 316L, 310S, 309S, etc., ratio=7.98. For 400 series stainless steel, ratio=7.75 A = Width, THK = Thickness, L = Length

Plastic Bag

Wooden case

By Sea

By Air