The question of which supplier of Slip On Stainless Steel Flanges is the best is not something to decide in haste.

When it comes to Slip On Stainless Steel Flanges, quality, reliability, and long-term trust are essential. Here’s what makes us stand out among slip on stainless steel flange suppliers. You can confidently rely on us for high-precision, corrosion-resistant stainless steel flanges that meet global industrial standards.

Understanding Your Needs

Before selecting a Slip On Stainless Steel Flange supplier, it is important to understand what these flanges are and why their quality plays a crucial role.

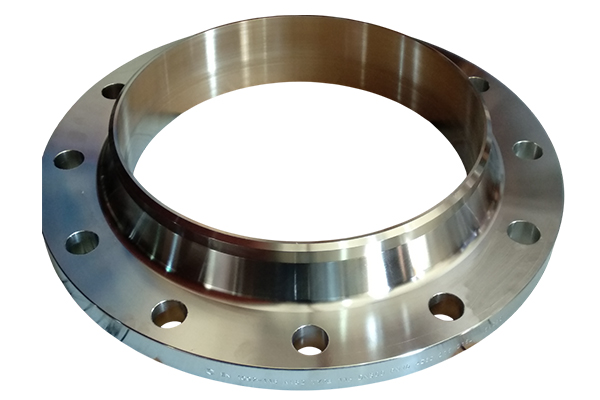

Slip On Stainless Steel Flanges are designed to fit over the pipe and are welded in place, providing strong sealing, easy installation, and excellent durability. In industries such as oil & gas, petrochemicals, water treatment, food processing, and power generation, the performance of a flange directly affects the safety and efficiency of the pipeline system.

Our stainless steel slip-on flanges ensure reliable performance by offering superior corrosion resistance, precise dimensions, and long service life. Manufactured from premium grades like SS 304, SS 316, and duplex stainless steel, they withstand high pressure, temperature variations, and harsh operating environments—making them ideal for both commercial and industrial applications.

With strict quality control, advanced manufacturing techniques, and timely delivery, we ensure consistent excellence for all your slip-on flange requirements.

| Property / Specification | Value / Range | Unit / Details |

|---|---|---|

| Material | SS 304, SS 316, SS 304L, SS 316L | - |

| Standard | ASME B16.5, ASTM A182, EN-1092, DIN, JIS | - |

| Pressure Class | 150, 300, 400, 600, 900, 1500, 2500 | - |

| Size Range | 1/2" to 24" (standard); up to 72" custom | NPS; Inch |

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) | - |

| Outer Diameter | 90mm (1/2″) up to 190mm (3″) and larger | mm, various sizes |

| Thickness | 9.6mm (1/2″), 22.3mm (3″), others | mm |

| Connection Type | Slipped over pipe and fillet-welded | Two welds required |

| Pressure-Temperature Chart | Standard charts as per ASME B16.5 | - |

| Surface Finish | 125–500 AARH; 3.2–12.5 Ra | µm |

Formula: m = (OD - THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926...

Plastic Bag

Wooden case

By Sea

By Air