Steelage Alloys is a reputable and foremost manufacturer of SS 304 Pipe Fittings in India and offers high quality pipe fittings manufactured out of stainless steel that is sent to perform at a high level of performance and with durability. We make ourselves a favorite option to the industries that are in need of long-lived and solution-precised stainless steel 304 fittings.

Our clients are spread throughout India and the rest of the world, and we have SS 304 Pipe Fittings that are in line with high international standards such as ASTM, ASME, DIN, and EN. Steelage Alloys can provide unparalleled quality, competitive prices, and delivery in time regardless of your requirement of either chemical processing, food industries, plumbing, construction, oil and gas, or marine.

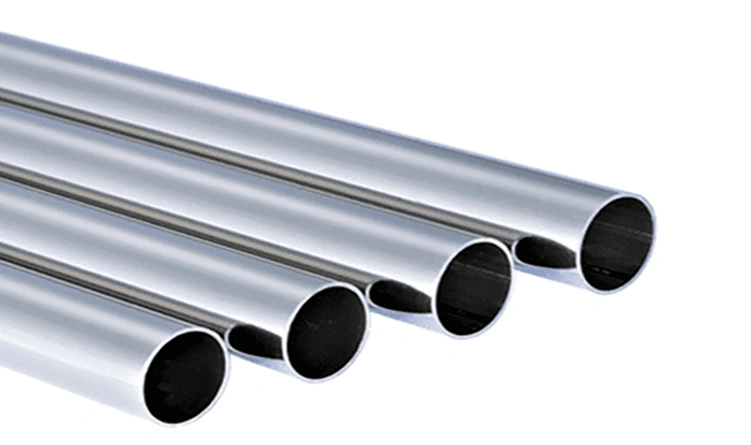

SS 304 Pipe Fittings are manufactured from Stainless Steel Grade 304, an austenitic stainless steel widely recognized for its excellent corrosion resistance, high strength, and easy fabricability. Grade 304 contains 18% chromium and 8% nickel, which gives it superior corrosion resistance and makes it suitable for a wide range of environments, including moist conditions, mildly corrosive chemicals, and outdoor applications.

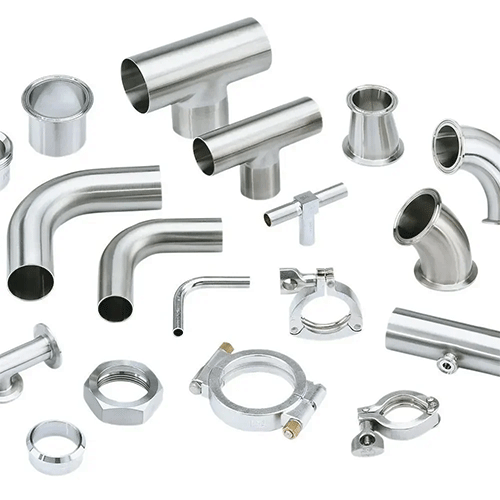

Our SS 304 Pipe Fittings are designed to provide seamless flow, leak-proof connections, and long-term durability in any piping system. With excellent machinability, weldability, and high-temperature strength, SS 304 Pipe Fittings are ideal for structural, pressure, and hygienic applications.

| Category | Details |

|---|---|

| Corrosion & Temperature Resistance | Excellent corrosion resistance in chloride environments; oxidation resistance up to 870°C intermittently. |

| Density | 8.00 g/cm³ |

| Modulus of Elasticity | 193 GPa |

| Thermal Conductivity | 16.2 W/m·K |

| Thermal Expansion | 17.2 × 10⁻⁶/K |

| Electrical Resistivity | 0.72 × 10⁻⁶ Ω·m |

| Melting Point | 1450°C |

| Heat Treatment | Does not harden by heat treatment; supports fabrication at high temperatures. |

| Hot Working | 1149°C – 1260°C followed by rapid cooling. |

| Cold Working | Requires intermediate annealing to prevent cracking. |

| Solution Annealing | 1010°C – 1120°C |

| Welding Recommendations | Use 308-grade fillers for fusion welding; post-weld annealing recommended for heavy sections. |

Formula: m = (OD - THK) × THK (mm) × L (m) × ρ (g/cm³) × π ÷ 1000

OD = Outside Diameter, THK = Wall Thickness, L = Length

ρ = Density, π = 3.1415926...

Plastic Bag

Wooden case

By Sea

By Air